Taizy 均质机 在高压和强烈冲击下精炼液体材料,有效改善牛奶和酸奶的质地、稳定性和质量。它广泛应用于现代乳制品生产线,制造出更顺滑、更白、更好喝的牛奶和酸奶。

我们的专业均质机设计用于100到2000升/小时的灵活生产能力,非常适合小型作坊和大型工业厂房,提供稳定可靠的加工效果和耐用的性能。

使用均质机的主要优势

- 均质机提高了产品的稳定性,有效防止分层,延长保质期。

- 均质产品具有更好的质地和更丰富的口感,特别是在制作牛奶、酸奶、酱料和奶油时,使其更光滑、更细腻。

- 此外,均质机还能显著改善产品外观,使乳制品看起来更亮丽、更均匀。

- 更重要的是,这款牛奶均质机均匀分散牛奶和酸奶中的脂肪和蛋白质,使产品质地更光滑,质量更稳定。

什么是均质机,它是如何工作的?

均质机旨在分解并均匀分散液体混合物中的颗粒。

当产品通过高压均质阀时,会被强制通过狭窄的缝隙,速度极快。突如其来的压力下降会破碎较大的颗粒(脂肪球或蛋白质团块),使其变成更小、更均匀分布的液滴。

这一机械过程改变液体的物理性质,使其变得更光滑、更稳定、更均匀。

高压均质机的应用

在乳制品加工行业中,均质化在改善牛奶、奶油和酸奶等产品的质地、颜色和稳定性方面起着关键作用。

在均质过程中,脂肪球被破碎成更小的液滴,并均匀分布在液体中。这防止了奶油分层,使牛奶外观更白,质地更光滑。脂肪和蛋白质的均匀分散使其质地更浓稠、更顺滑,改善口感。

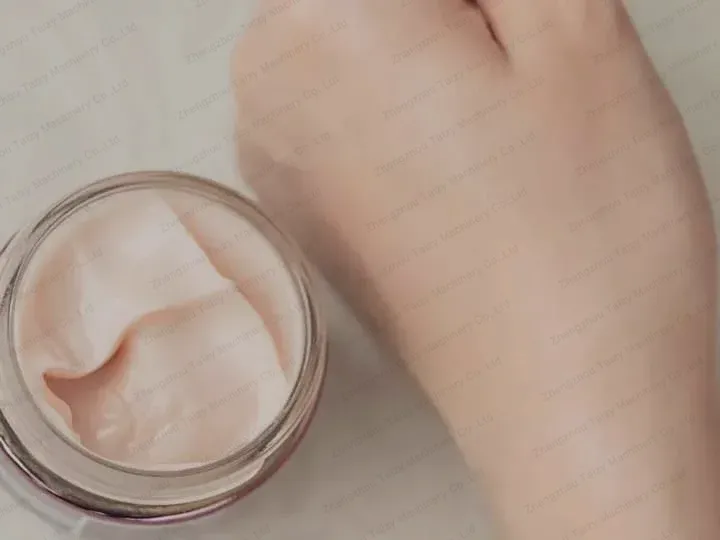

此外,均质机还被应用于化妆品行业,用于生产具有均匀质地的面霜、乳液和精华液。它们能细致分散活性成分,乳化油性和水性成分,形成光滑、稳定、持久的配方。

均质机的型号和技术参数

| 模型 | GJJ-0.1/25 | GJJ-0.2/25 | GJJ-0.3/25 | GJJ-0.5/25 | GJJ-1/25 | GJJ-2/25 |

| 流动 | 100升/小时 | 200升/小时 | 300升/小时 | 500升/小时 | 1000升/小时 | 2000升/小时 |

| 最大压力 | 25兆帕 | 25兆帕 | 25兆帕 | 25兆帕 | 25兆帕 | 25兆帕 |

| 工作压力 | 20兆帕 | 20兆帕 | 20兆帕 | 20兆帕 | 20兆帕 | 20兆帕 |

| 电机功率 | 1.5千瓦 | 2.2千瓦 | 3千瓦 | 4千瓦 | 7.5千瓦 | 15千瓦 |

| 尺寸 | 755*520*935毫米 | 755*520*935毫米 | 755*520*935毫米 | 1010*616*975毫米 | 1100*675*1065毫米 | 1410*850*1190毫米 |

成功案例:

我们有一个来自沙特阿拉伯的长期客户,是一家乳制品生产商。两年前,他从我们这里购买了一条完整的2吨酸奶生产线,包括巴氏杀菌系统、发酵罐、灌装机等。它帮助他的公司成功推出了几款酸奶产品,在当地市场非常受欢迎。

一年后,我们的客户注意到,虽然他的酸奶味道鲜美、清新,但在储存过程中偶尔会出现轻微的乳清分离,而且批次之间的质地也存在差异。

经过我们技术人员与客户多次讨论,最终决定升级生产线,增加高压均质机,以改善发酵前牛奶的均匀性和稳定性。

在均质机投入生产两个月后,产品效果显著。不仅使酸奶中的脂肪和蛋白质分布更加均匀,显著减少乳清分离,还改善了酸奶的质地,即使在长时间冷藏下也能保持良好的口感。

现在,该品牌的高端酸奶系列已成功进入多个大型本地超市连锁,改良的酸奶品质带来了更多订单。

“我们最初选择Taizy,是因为他们提供完整的酸奶生产线。当我们想进一步提升质量时,Taizy推荐了均质机。现在我们的酸奶更白、更浓厚,口感更佳。”

如果您想开发自己的酸奶生产线或单独购买机器,请联系我获取最新报价和折扣!

更多关于酸奶产品的信息,请点击: