Homogenizer machines refine liquid materials under high pressure and strong impact, effectively improving the texture, stability, and quality of milk and yogurt. It is widely used in modern dairy production lines to create smoother, whiter, and better-tasting products.

Taizy milk and yogurt homogenizer is designed for flexible production capacities ranging from 100 to 2000 L/h, which makes it ideal for both small-scale workshops and large industrial plants, providing stable and reliable processing results and durable performance.

Key advantages of using a homogenizer machine

- The homogenization improves product stability, which effectively prevents separation and extends shelf life.

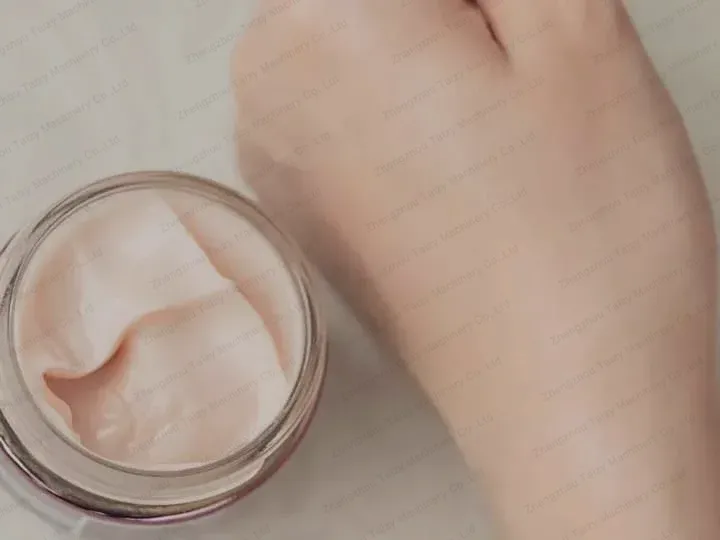

- Homogenized products have a better texture and more flavorful taste, especially making milk, yogurt, sauces, and cream smoother and more delicate.

- In addition, homogenizers can significantly improve the appearance of products, making dairy products look brighter and more uniform.

- What’s more, homogenization evenly disperses fats and proteins in milk and yogurt, giving the product a smoother texture and more consistent quality.

What is a homogenizer machine and how does it work?

A homogenizer is designed to break down and uniformly disperse particles in a liquid mixture.

When the product passes through a high-pressure homogenizing valve, it is forced through a narrow gap at extremely high speeds. The sudden pressure drop forces the breakdown of larger particles(fat globules or protein clumps) into smaller, more uniformly distributed droplets.

This mechanical process changes the physical properties of the liquid, resulting in it becoming smoother, more stable, and more homogeneous.

Applications of the high-pressure homogenizer

In the dairy processing industry, homogenization plays a crucial role in improving the texture, color, and stability of products such as milk, cream, and yogurt.

During homogenization, fat globules are broken down into smaller droplets and evenly distributed throughout the liquid. This prevents cream separation, resulting in a whiter appearance and smoother texture for the milk. The uniform dispersion of fat and protein results in a thicker, smoother texture, improving its taste.

In addition, homogenizers are also adapted in the cosmetics industry for producing creams, lotions, and serums with uniform textures. They finely disperse active ingredients and emulsify oily and water-based components, resulting in smooth, stable, and long-lasting formulations.

Models and technical parameters of the homogenizer machine

| نموذج | GJJ-0.1/25 | GJJ-0.2/25 | GJJ-0.3/25 | GJJ-0.5/25 | GJJ-1/25 | GJJ-2/25 |

| تدفق | 100L/h | 200L/h | 300L/h | 500L/h | 1000L/h | 2000L/h |

| Max pressure | 25 ميجا باسكال | 25 ميجا باسكال | 25 ميجا باسكال | 25 ميجا باسكال | 25 ميجا باسكال | 25 ميجا باسكال |

| ضغط العمل | 20 ميجا باسكال | 20 ميجا باسكال | 20 ميجا باسكال | 20 ميجا باسكال | 20 ميجا باسكال | 20 ميجا باسكال |

| قوة المحرك | 1.5kw | 2.2 كيلو واط | 3kw | 4 كيلو واط | 7.5kw | 15kw |

| Dimensions | 755*520*935mm | 755*520*935mm | 755*520*935mm | 1010*616*975mm | 1100*675*1065mm | 1410*850*1190mm |

Successful case:

We have a long-term client from Saudi Arabia, who is a dairy producer. Two years ago, he purchased a complete 2t yogurt production line from us, including a pasteurization system, fermentation tanks, filling machines, etc. It helped them successfully launch several yogurt products, which became very popular in the local market.

A year later, our customers noticed that while their yogurt was flavorful and fresh, it occasionally experienced slight whey separation during storage, and there were also variations in texture between batches.

After several discussions between our technicians and him, it was finally decided to upgrade the production line and add a high-pressure homogenizer to improve the uniformity and stability of the milk base before fermentation.

After the homogenizer machine was put into production for two months, the product results were remarkable. Not only was the distribution of fat and protein in the yogurt more uniform, significantly reducing whey separation, but the texture of the yogurt also improved, maintaining a good taste even under prolonged refrigeration.

Now, the brand’s premium yogurt series has successfully entered several large local supermarket chains, and the improved yogurt quality has brought in more orders.

“We initially chose Taizy because of their complete yogurt production line. When we wanted to further improve the quality, Taizy recommended the homogenizer. Now our yogurt is whiter, thicker, and tastes better.”

If you want to develop your own yogurt production line or purchase a machine separately, please contact me for the latest quote and discounts!

For more information on yogurt products, click here: