Tube-type yogurt making machine is mainly used to make high-yield yogurt. Thanks to a high-temperature sterilizer, yogurt sterilization can be completed in a few seconds, which greatly improves working efficiency, but it can still retain its nutrition of milk. The most significant feature of this yogurt production line is that the sterilization is continuous in a completely closed system. Besides, such a sterilization system has little effect on the flavor and nutritional content of the final yogurt, preventing the secondary pollution of milk.

Why to choose us to purchase yogurt processing machine?

This yogurt-making machine is equipped with an efficient and reliable sterilization system, and the heating source is effectively used to reduce energy consumption to the minimum. At the same time, intelligent PLC control saves manpower, and the design of the CIP system can meet the cleaning requirements. Compared with the traditional yogurt production line, the yogurt produced by this tube type has a longer expiration life. Its output can reach 1-5t per day, we can also customize it according to your requirements.

The features of high-temperature tube sterilization part

The working steps of tube-type yogurt making machine

Like other yogurt-making equipment, the working step of this tube-type yogurt machine is as follows, storage tank,preheating tank,homogenizer tan,tube-type high-temperature sterilization part,fermentation tank, and yogurt filling machine. What the difference lies in the tube high-temperature sterilization part, and the milk enters the pump for sterilization, and then to be cooled to the fermentation temperature. Yogurt sterilization heating uses superheated water as the medium, and the adjustment of the filling outlet temperature uses cooling water, which enables the accuracy of temperature control.

The application of high temperature sterilizer

- High-temperature sterilizer can be used for heating various dairy products, juices, beverages, syrups, soy sauces, wines, vinegar etc.

2. It is suitable for heating or cooling non-corrosive liquids, and also bears heat preservation and heat recovery.

3. Tube type sterilizer can also automatically control and record the sterilization temperature of raw materials, and automatically return the unqualified materials.

The temperature and UHT flow adjustment during yogurt processing line

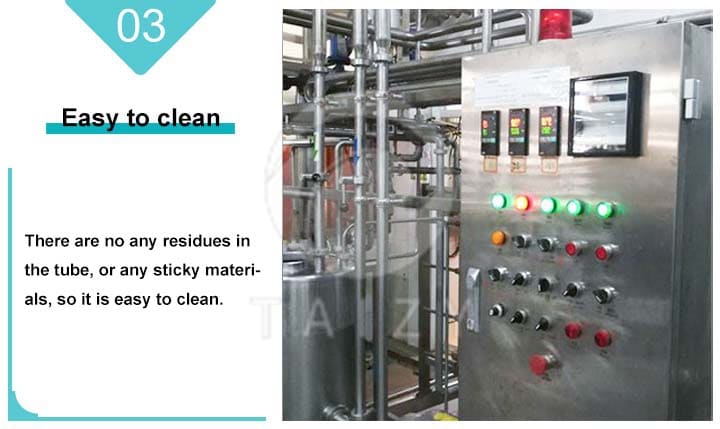

1. Control and adjustment of sterilization temperature: The sterilization temperature can be set according to customer needs. The yogurt making machine can be controlled by PLC in a fully automatic and intelligent way according to the set temperature, maintaining its accuracy.

2. Adjustment and control of milk discharging temperature: The temperature of yogurt discharging should be 65 ~ 92 ℃. The milk outlet temperature can be set as required.

3. UHT flow adjustment and control: Refer to the flowmeter indicator, you need to adjust the UHT outlet flow manually

The advantage of tube type yogurt making machine

1. Yogurt has high thermal efficiency, after heating, 90% of the heat energy can be recovered.

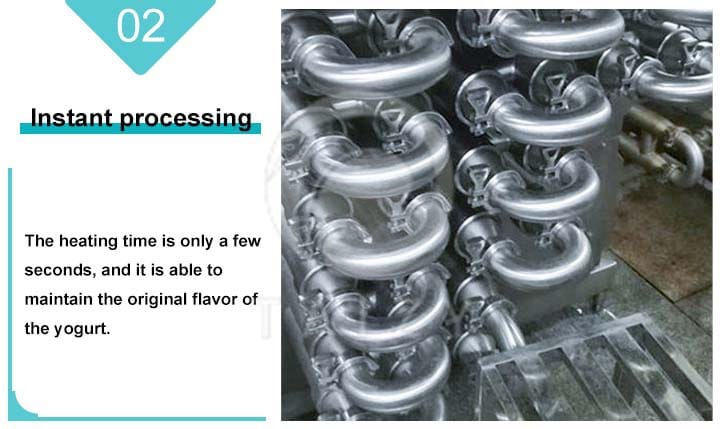

2. The inner wall of the pipe is polished and welded by advanced technology, what’s more, the pipe can be automatically cleaned. The whole process is automatically sterilized to ensure the sterility of the system.

3. Yogurt making machine can precisely control the sterilization temperature and retain the nutrition in the yogurt to the maximum extent.

4. Gentle heating can be achieved with less residue, which increases the continuous working time of the sterilizer.

5. There are alarm systems and pressure protection measures to ensure the safety of workers.

6. High degree of automation. The entire process from pipeline sterilization to CIP cleaning can be automatically controlled and recorded.

7. Reasonable pipe design, automatic cleaning.

8. UHT sterilization system adopts a human-machine interface and PLC centralized control with touch screen. Operators can control and monitor the entire yogurt processing online.

How to install and test tube-type sterilization part?

1. All the yogurt making machines should be disinfected before use, and then you can place the milk.

2. When feeding milk, you should open the low-pressure valve firstly, and then open the other side.

3. When opening the valve, do not suddenly expand the milk flow. The yogurt processing machine should be used within the specified pressure and range. The over-temperature operation will damage the sealing performance and cause leakage.

4. Seals should be placed at the pipe joints to prevent the yogurt from leaking.

5. The installation of control circuit components and wires should avoid steam and hot water pipelines, otherwise, it will affect the normal operation of the machine.