The yogurt fermentation machine is a device that provides a constant temperature(35-45 degrees centigrade) for milk fermentation. Under this environment, probiotics multiply at an amazing speed, and the lactose in milk is converted into lactic acid, and then fermented into yogurt. Adopting pasteurization and electric heating, the yogurt produced by this yogurt maker is solidified, besides, it is rich in milk flavor and adjustable in taste. It can be divided into single-door yogurt ferment machines and double-door yogurt fermentation machines.

It also can mix with jam, honey, lemon, fruit juice, etc, and it is safe, hygienic, green and healthy with excellent taste. Taizy frozen yogurt machine is widely used in yogurt shops, tea restaurants, cake shops, coffee shops, bakeries, western food shops, beverage shops, supermarkets, frozen food factories, etc.

The Technical parameter of double-door yogurt fermentatation machine

| Model | TZ-760 |

| Heating power | 2kw |

| Cooling power | 0.3kw |

| Fermentation temperature | 0-60℃ |

| Refrigeration temperature | 0-8℃ |

| Dimension | 1200*700*1950mm |

Single-door yogurt yogurt ferment machine technical parameter

| Model | TZ-38 |

| Heating power | 1kw |

| Cooling power | 0.23kw |

| Fermentation temperature | 0-60℃ |

| Refrigeration temperature | 0-8℃ |

| Dimension | 650*700*1950mm |

Technical parameter of temperature

| Model | Double-door frozen yogurt machine | Single-door frozen yogurt machine |

| Fermentation temperature | 43-47℃ | |

| Fermentation temperature fluctuation | ±0.5℃ | |

| Fermentation temperature uniformity | ±1.5℃ | |

| Refrigeration temperature | 4.5℃ | |

| Refrigeration temperature fluctuation | ±1.5℃ | |

| Voltage | 220v 50HZ | |

| Ambient temperature | 0-35℃ | |

| Volume | 500L | 300L |

| Heating power | 0.8kw | 0.4kw |

The advantage of yogurt fermentation machine

1. Refrigeration and fermentation are performed in the same place, saving production costs.

2. The frozen yogurt machine is able to automatically locked to provide sufficient conditions for lactic acid bacteria fermentation.

3. The produced yogurt does not have any additives, harmful colors and pigment. What’s more, it is healthy, nutritious and fresh, meeting the human body’s needs for different acidity.

4. Yogurt maker can perform constant fermentation temperature, and lactic acid bacteria can multiply quickly at a suitable temperature.

5. The outside bacteria will not invade the yogurt during operation, and it is clean and hygienic.

6. The refrigeration compressor and exhaust fan can quickly cool down, changing the traditional yogurt’s deterioration in time because the storage temperature cannot meet the requirements.

7. The ultraviolet sterilization lamp can be quickly sterilized so that the entire production and storage process is always sterile and pollution-free.

The precaution of commercial frozen yogurt machine

1. The tilt of frozen yogurt machine during transportation should exceed 30 degrees.

2. In order to allow the compressor oil to settle, the commercial frozen yogurt maker cannot be operated for the first 6 hours after it is installed, otherwise, the cooling effect is not good.

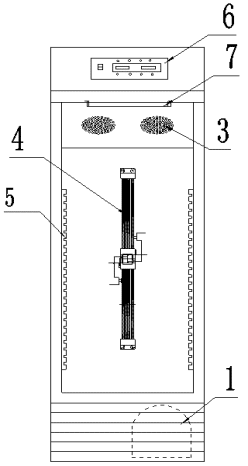

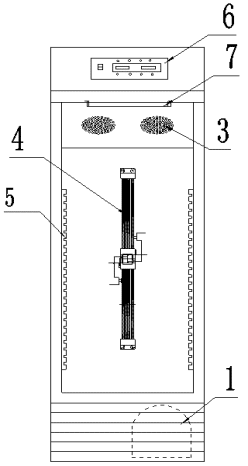

The structure of yogurt making machine

double-door yogurt machine

| Picture | Spare parts | Type | Number |

| compressor | double door | 1 |

| heat sink | double door | 1 | |

| fan | double door | 3 |

| heating wire | double door | 4 | |

| temperature sensor | double door | 1 |

| sterilization lamp | double door | 2 |

| wheel | double door | 4 |

How to arrange the yogurt cup?

1. Yogurt cups should not be stacked too densely, and there should be enough space to make the air in the yogurt maker smooth, which is conducive to the rapid heating of fresh milk or the rapid cooling of final yogurt.

2. The height of the yogurt cup must not exceed the height of the machine.

3. The yogurt cup should be evenly distributed.

The workflow of yogurt fermentation machine

1. First, sterilize the operation table and yogurt machine with 75% medical alcohol.

2. Then you should use pasteurize. The sterilization temperature is 85 degrees Celsius, when the temperature is greater than 50 degrees Celsius, it should be stirred every 15 minutes.

Note: Do not add sugar directly to the yogurt, and you can first dilute the sugar with milk by a small cup, and then pour it into the milk tank.

3. When the temperature drops to 45 degrees Celsius after sterilization, you should add the bacteria evenly to the yogurt. Stir it around 3 minutes.

4. Place the yogurt into a paper cup and place it in the machine.

5. Turn on the sterilization lamp to sterilize, and then ferment for 8 hours.

6. Finally, refrigerate for about 10 hours.

Note: The time of fermentation and cooling is around 24 hours. The longer the refrigeration time is, the better the taste will be.

Why the yogurt maker can not refrigerate?

Reason

1. The compressor does not work

2. The radiator is not working

3. Frozen yogurt machine is not able to cool or the temperature drops very slowly.

Solution

1. Stop the machine and open the protective net below the body to replace the compressor.

2. Replace the radiator.

3. Fill the refrigerant.