Yogurt is loved by consumers and has become one of the most frequently consumed foods. so it is a good opportunity to start a yogurt production business .and yogurt is an ideal health drink, and it is more nutritious than milk. It can help digestion, increase appetite, It has a therapeutic effect on chronic patients with mild diarrhea. Therefore, yogurt is a flavored food with both diet and health care. Developing the brewed yogurt production business requires less investment and more profits.

Yogurt production business production method

1. Choose whole milk at room temperature! Do not choose skimmed or low-fat milk and milk powder

2. Before making yogurt, the inner tank of the yogurt machine needs to be cleaned with hot water and detergent to prevent bacteria from attaching to the oil and dust to survive (must be done every time);

3. Put half of the milk first, then put a bag of bacterial powder and stir (1 small bag of bacterial powder can make 500~1000ml of milk), then pour the other half of the milk and stir evenly (stir for a while), and we recommend adding 50g to 1L of milk White sugar, you can put it with the fungus powder before cooking, or add it when you eat it, be sure to stir until it melts;

4. Add about 45° warm water between the yogurt maker and the container (not used in summer);

5. Put it in the yogurt machine, do not open the lid during production, ferment for 7~8 hours in summer, 10~12 hours in spring and autumn, and 12~15 hours in winter;

6. It can be eaten immediately after fermentation. and must be sealed and refrigerated. It tastes better after 16 hours of refrigeration;

Precautions for making yogurt

1. After receiving the bacteria, please put it in the freezer of the refrigerator for storage.

2. It is best to choose instant ultra-high temperature sterilized UHT pure milk for making yogurt.

3. When adding bacterial powder, stir while sprinkling, and be sure to stir evenly.

4. The focus of making yogurt is hygiene. Clean the inner tank of the yogurt machine with detergent and warm hot water. Rinse it with clean water without residue. Wipe it with a special scouring pad without oil.

5. Add 50g of sugar per liter of milk, you can add it first or later, you can’t use the sugar scattered in the kitchen, it may be contaminated.

6. Yogurt is not fermented as long as possible. The best time to add probiotics to fermented yogurt is under the premise of room temperature 26℃. The yogurt machine heats the milk to 42℃ and keeps the temperature for 6 hours. At this time, the probiotic activity is the highest. ;

7. Use normal temperature milk to make yogurt, and finish fermentation in 8 hours at room temperature of 26℃.

8. When making yogurt with milk taken out of the freezer, it takes 4 hours longer than normal.

9. After the yogurt is fermented, put it in the refrigerator immediately, otherwise, it will continue to ferment.

10. Do not uncover frequently during the process of making yogurt, otherwise, the air will affect the fermentation.

11. When the fermentation temperature is lower than 36°, the probiotics cannot be activated and the fermentation is slow. When the milk temperature is higher than 45°, the bacteria cannot be added, and the bacteria will be killed.

Classification of yogurt production business:

From the difference in technology, yogurt is divided into stirring type and solidified type. The two have a slight difference in taste (solidified yogurt tastes sourer), but there is no difference in nutritional value. In terms of raw materials and additives, yogurt is mainly divided into plain yogurt, flavored yogurt, and fruit yogurt. Pure yogurt is fermented with milk or reconstituted milk as raw materials; flavored yogurt or fruit yogurt is fermented by adding sugar, flavoring, or natural fruit to milk or reconstituted milk. Currently, flavored yogurt and fruit yogurt are the main products. From the perspective of fat content, there are full-fat yogurt, low-fat yogurt, and non-fat yogurt.

Solidified yogurt: After inserting the bacteria, it is put into retail containers first, and then kept warm and fermented. The finished product is solidified in the container.

Stirred yogurt: The starter produced in Baojiang is inoculated in the fermenter with the flying petals of the growing stalks. After solidification, it is stirred and put into a cup or other container.

Pure yogurt: It is a product made from milk or reduced milk and fermented, and no other auxiliary materials should be added.

Flavored yogurt: It is made by adding various flavors to natural yogurt or sugared yogurt, which is more common in the market.

Fruit-based yogurt: It is made by mixing pure yogurt, sugar, and natural fruit materials.

Functional yogurt: used for people with specific needs, such as low-lactose yogurt, low-calorie yogurt, vitamin yogurt, or protein-fortified yogurt, etc.).

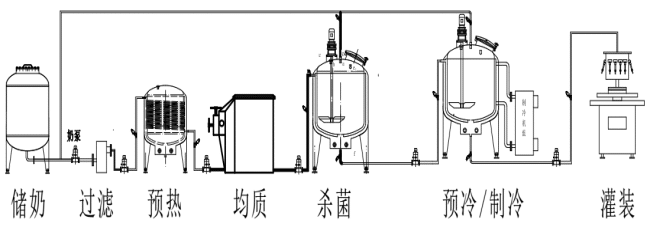

Yogurt production business equipment

There are many aspects to pay attention to in the yogurt production business, but the more important thing is to have a good yogurt production line. The yogurt production line varies according to the output of different equipment models. For example, there are 200-500L production lines and 1T-5T production lines.