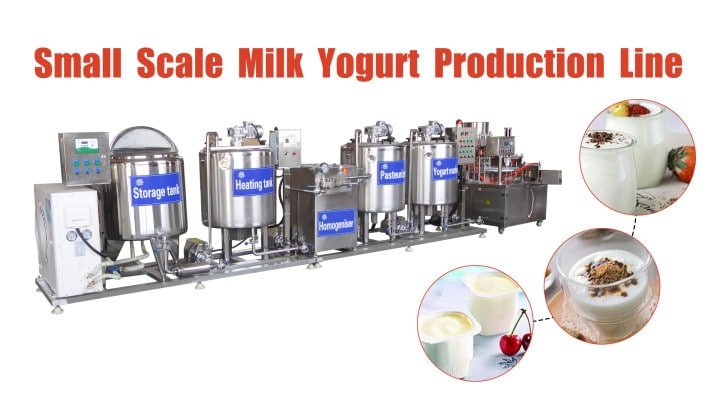

Yogurt Production is a project that many producers want to try. It is true that there is a large profit margin for yogurt production, and the process of yogurt production is relatively easy to master. Many producers find us and want the smallest yogurt production line as a try. The smallest yogurt production line we can provide is a 200L line. Although the output is small, the production steps and equipment are still complete.

Types of yogurt

If you want to produce yogurt, you first need to understand what types of yogurt are available. Yogurt is divided into stirred yogurt and solidified yogurt. Yogurt is processed from fresh milk. The milk is usually squeezed out and then quickly refrigerated, and then processed in a ranch or dairy. A homogenizer is generally required to make yogurt. After the milk is homogenized, Can effectively crush and disperse, make the mixing more uniform.

Reasons that affect the quality of yogurt

The small yogurt production line actually only makes yogurt for many reasons. For example, the milk source, the equipment used, the strain, the processing method, etc. are different, and the difference in the yogurt produced is also quite big. Good-quality yogurt is basically fermented with high-quality and qualified fresh milk. The yogurt produced by the injected cow is not usable. I have a source of milk, and I only need to order a set of high-quality and qualified equipment to process high-quality yogurt.

CIP helps complete yogurt cleaning of Small Scale Commercial Yogurt Production

The cleaning of yogurt production line equipment is very cumbersome and also a headache for customers. A little improper cleaning will cause serious consequences for the growth and reproduction of microorganisms. The main purpose of cleaning is to remove some microorganisms that may exist, reduce pollution sources, and prevent the processing of different products. A mix of scents.

The flushing effect of small yogurt processing equipment is directly related to the quality of the next processed product. If the small yogurt equipment is not cleaned, the milk or milk-water mixture will deteriorate in the dead corner. Once the deterioration occurs, the colony index of the second milk processing will verify that it exceeds the standard, and the whole batch of milk is unqualified. The CIP cleaning system of small yogurt processing equipment can ensure a certain cleaning effect.